Last week Black Diamond expanded its range by two large Camalots. The mobile fuses are now available in sizes 7 and 8. In today's article, the specialists at Black Diamond are asking the following question: Are larger Camalots also more stable fuses?

A guest post by Black Diamond

The new C4 # 7 & # 8 are huge camalots and are among the largest on the market. In addition, a C4 # 5 looks small and handy. These giant beasts were designed to secure the dreaded off-width cracks found on El Cap and other famous crack climbing areas.

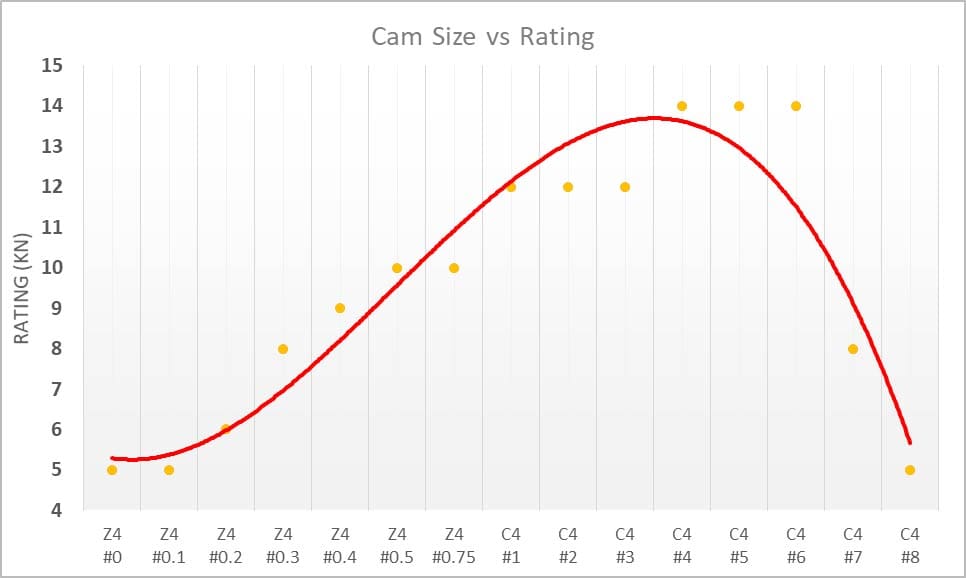

This year we've released the smallest and largest Camalots ever made - the Z4 # 0 micro size and now these big boys. At first glance, these sizes actually have nothing in common, but that's not entirely true. Size plays a role in the perception of the strength of a Camalot. It is much more confidence-inspiring to plunge into or hang from a hand-sized Camalot than into a tiny Camalot for the finest cracks. This applies to the majority of our sizes up to a certain point that can be achieved with these extra large Camalots.

In this QC Lab we will examine, compare and compare the performance of the C4 # 7 and # 8 and the Z4 # 0 and show why the rating of these particularly large Camalots is closer to that of the Micro Camalots than you might think.

Before we delve into the test results, it's important to understand some of the key definitions that are used consistently.

Ultimate strength (breaking load)

Refers to the load that causes the Camalot to fail; this is usually given in kilonewtons. These values result from slow loading of the Camalot in various “cracks” with a defined size based on the expansion range of the clamping segments. The minimum breaking load must be 5 kN in order for a Camalot, also known in the official language as a clamping device, to meet CE requirements.

Percentage Retraction & EN 12276 Mountaineering Equipment - Clamps

In order for personal protective equipment (PPE) to be sold in Europe, it must be CE certified. Each equipment category has its own specific requirements, which are set out in the EN standard; for Camalots the standard EN 12276 - clamping devices applies. There are many requirements to meet this standard, including those for markings, instructions for use, the use of materials, etc. But the most important one that we will examine here is the breaking strength or breaking load.

There are two main destructive tests that a Camalot has to go through to be certified: with a load of 25% and with 75% collapsed clamping segments. These tests simulate a less than ideal, rather unsafe placement with 25% collapsed segments and a better, preferred placement with 75%. The following formulas are used to find the appropriate placement widths, where Bmin refers to the collapsed width and Bmax to the full, non-collapsed width of the Camalot.

Note: If a Camalot has an expansion range of 5 mm or less, the CE standard stipulates that it must be checked 50% when folded (instead of 25% or 75%). The Z4 # 0 fulfills this requirement.

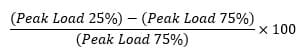

Percentage reduction in strength

To show the difference in strength between 25% and 75%, the percentage strength reduction is determined using the following formula.

Ratings

The rating given is the breaking load limit that the product can consistently meet under the test conditions, according to the manufacturer. The minimum breaking load specified in the CE standard is 5kN. The markings on a Camalot's sling can have two indications - one for active strength (a normally placed Camalot) and one for passive strength (a clamp that is used as a stopper). With the Black Diamond Camalots, the passive strength is only given for the versions with double axles.

This does not necessarily mean that a Camalot fails at 8 kN if it is rated 8 kN. The ratings are determined and calculated using a so-called three-sigma calculation. The lower three sigma limit can be found by testing a statistically relevant sample and determining the mean (µ) and the standard deviation (σ). From this it can be deduced that 99,7% of all failure events with a load will be above the lower limit. This is the starting point for determining the published breaking load. After considering the various applications of the product, the breaking load could be further reduced.

Lower Bound = µ - 3 * σ

Lower 3-sigma calculation used in the determination of the breaking load

Classification of the Camalot size

For this article, certain sizes are referred to as Small, Medium and Large, the breakdown of each size is listed below.

Small - Camalot sizes Z4 # 0 to Z4 # 0.4

Medium - Camalot sizes Z4 # 0.5 to C4 # 2

Large - Camalot sizes C4 C4 # 3 through C4 # 8

This is how Black Diamond tested the Camalots

Regardless of the size of the Camalot, you should always aim for the best possible placement, but this is not always feasible. There are bumps in the rock, you have a limited number of camalots to use along a pitch, and sometimes you just want to put something in the crack rather than have nothing. But how much do these uncertain placements affect the strength of the Camalots at either end of the spectrum?

As with all QC Labs, it is important to note that we are dealing with a small sample size and tests under fairly ideal conditions. The test setup includes precise measurements in a configuration with steel plates in order to avoid deviations as far as possible.

For the sake of simplicity, we have limited ourselves to two different tests:

Test 1: CE standard test

Based on the CE standard - with the Z4 # 0, C4 # 7 & # 8 and a large number of Camalots in the medium size range.

- To determine the percentage reduction in strength when comparing the results with 25% versus 75% collapsed clamping segments and ...

- In order to be able to compare small and large sizes in both CE test configurations directly

Test 2: Non-standardized asymmetric test

- A non-standardized asymmetric test of only the larger C4s.

- To show the realities and limitations of placing larger camalots.

Test 1

CE standard test - analysis

The following table shows the results of the test according to the CE standard (for the sake of simplicity, not every Camalot size is shown).

* Testing according to the CE standard is not required, but is included in the table for the sake of completeness

If we look at the results in Table 1, there are several important observations:

- Overall, the breaking strength is higher than in a normal field load scenario. It's good. This means that if a Camalot is placed well, it can easily fall.

- For the medium sizes tested, the difference in results between the 75% and 25% collapsed clamping segments is negligible.

- For sizes Z4 # 0.5 & # 0.75 and C4 # 1 there is hardly any difference in breaking strength between the two test scenarios.

- The clamping segments in these sizes enable particularly secure placement, with enough room to allow the clamping segments to move slightly without them becoming unstable or turning around.

- These sizes have a higher fault tolerance and can adapt somewhat better to unfavorable positions.

- For larger clamping segments, however, the percentage reduction in strength between the two test scenarios increases.

- When they are folded 25%, the medium-sized Camalots come in contact with the rock with little material, and the device swerves at a lower load than at 75%.

- For the largest Camalots, the percentage reduction in strength is due to the fact that the clamping segments have instability and a tendency to buckle.

- With the Z4 # 0 it is stipulated in the standard due to the limited expansion range that this Camalot is only checked 50% when folded, which of course does not allow a calculation of the percentage strength reduction. This fact illustrates that the Camalot, when folded only 25%, has little stability and underlines the need for precise and secure placement.

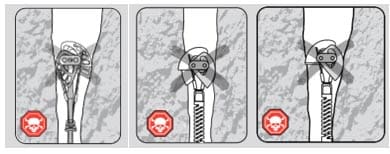

CE standard testing - differences in failure

Camalots can fail in different ways:

- In the case of the Z4 # 0, the scope is very limited and the contact area with the rock is minimal. During the test, it is normal for the clamping segments to shift slightly as the load increases. With # 0, the rotation required to move from 50% to 0% when collapsing is minimal, which causes the Camalot to fail quickly. The most common failure is that the cams reverse and tear out of the placement.

- With smaller Camalots, the cable typically fails in the thumb area if the placement is good.

- With some medium-sized Camalots, when they are folded 25%, only little material comes into contact with the rock. The aluminum of the clamping cam then shears out under load.

- With the really big Camalots, the # 7 and # 8, the axles can bend if they are positioned well and the clamping segments can break or buckle. When the clamping segments are folded in by 25%, they always kink. This effect is amplified with any slight shift or misalignment.

CE standard test - summary

If the large Camalot is only minimally folded in, the strength of the device can be considerably reduced due to the tendency of the clamping segments to buckle. If the Micro-Camalot is only folded in minimally, the strength of the device can also be considerably reduced because the clamping segments can turn around. While both Camalot sizes fail at very different points, their sensitivity to unsafe positions remains almost the same.

Camalots get weaker when completely closed - fact or false assumption?

As a side note, it should be mentioned that the more a Camalot is folded, the more firm it is. It is often said that a Camalot is weaker when placed fully collapsed. Some call this situation "over-cammed". However, that is not true. The more the clamping segments are folded in, the greater the strength of the Camalot. The only disadvantage is that it is much more difficult to free a fully collapsed Camalot from the crack without damaging the device or the rock.

TEST 2

NON-STANDARD ASYMMETRIC TEST

During the development of a new product here at Black Diamond, in addition to the tests according to the CE standard, there are many tests that are created and carried out to validate the product. These tests are carried out to better understand the effects of potential misuse that can occur in practice. One of these tests is to hold the Camalot at an angle outside the direction of pull to see what happens. All of the tests described in this article were performed under ideal conditions and placements.

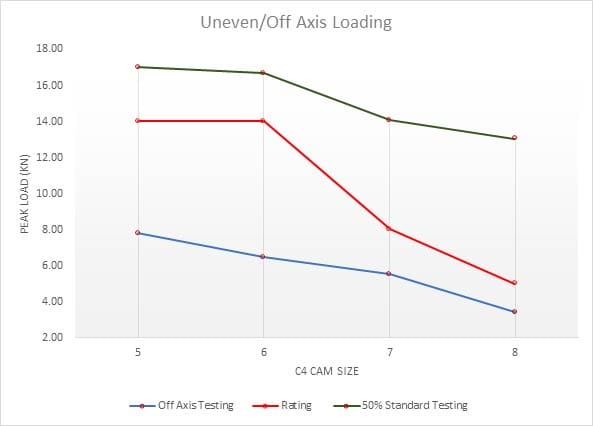

So what about the strength of large Camalots when they are placed outside the direction of pull?

This second round of testing was performed on the larger C4 sizes (# 5, # 6, # 7, # 8). They were placed with a deviation of about 30 degrees from the vertical and about 50% collapsed, with the individual clamping segments being collapsed unevenly. In many cases, the Camalot will orient itself in the direction of the pull, but this test prevented this behavior in order to present a worst-case scenario.

Results of the non-standardized asymmetric test

NON-STANDARD ASYMMETRIC TEST RESULTS

Previous tests have shown that the greater the size, the greater the instability. The following are key components of the large C4's degraded performance under uneven loading:

- Positioning the Camalot in this orientation increases the tendency of the device to bend out of the plane.

- In this scenario, the extent to which the clamping segments have been folded in plays an important role. The further the clamping segments are folded in, the higher the stability of the Camalot, which improves its resilience. These tests were done at 50%. This is not the worst case scenario, but ideally the Camalot would be used even more when folded down.

- Starting with the C4 # 5, the strength decreases at a constant rate up to a load that is significantly lower than in a test with proper placement.

- As the size of the clamping segments increases, the moment force acting on the segments also increases, which contributes to the lower breaking loads.

- With uneven loading, individual clamping segments are exposed to higher forces than others. Therefore, slight irregularities can cause the kink to break faster than if the load were evenly distributed over all four clamping segments.

NON-STANDARD ASYMMETRIC TEST SUMMARY

Large Camalots are more susceptible to strength reduction than smaller ones if they are placed outside the direction of pull. It is important that large Camalots are placed so that they are oriented in the direction of tension or loading, whereby the individual clamping segments should be folded in as evenly as possible and as far as possible.

CONSERVATIVE RATINGS

At Black Diamond, when we assign a rating to the Camalot size, we take into account more than just the standard CE requirements. The results of our internal tests are also heavily included.

If we look at the previous test results, the breaking load is well above the 5kN rating (for Z4 # 0 & C4 # 8) and the 8kN rating (for C4 # 7). Due to the known restrictions and the sensitivity for placements, however, a conservative rating was chosen to underline the need to always strive for the best possible placement when climbing.

CONCLUSION

It is very unlikely that any crack climbing placement will be perfect, and some sizes are easier to accept than other sizes. While every Camalot should be placed with caution, particular caution should be exercised with the sizes at either end of the spectrum.

Sufficiently folded clamping segments and symmetrical loading are the key to a good placement.

Even if a particularly large Camalot can give the appearance of a strong and reliable fuse, its breaking load limit is similar to that of a Micro-Camalot and must be treated as such before deciding to take on the challenge of a difficult off-width monster.

+ + +

Credits: Images by Andy Earl / Black Diamond